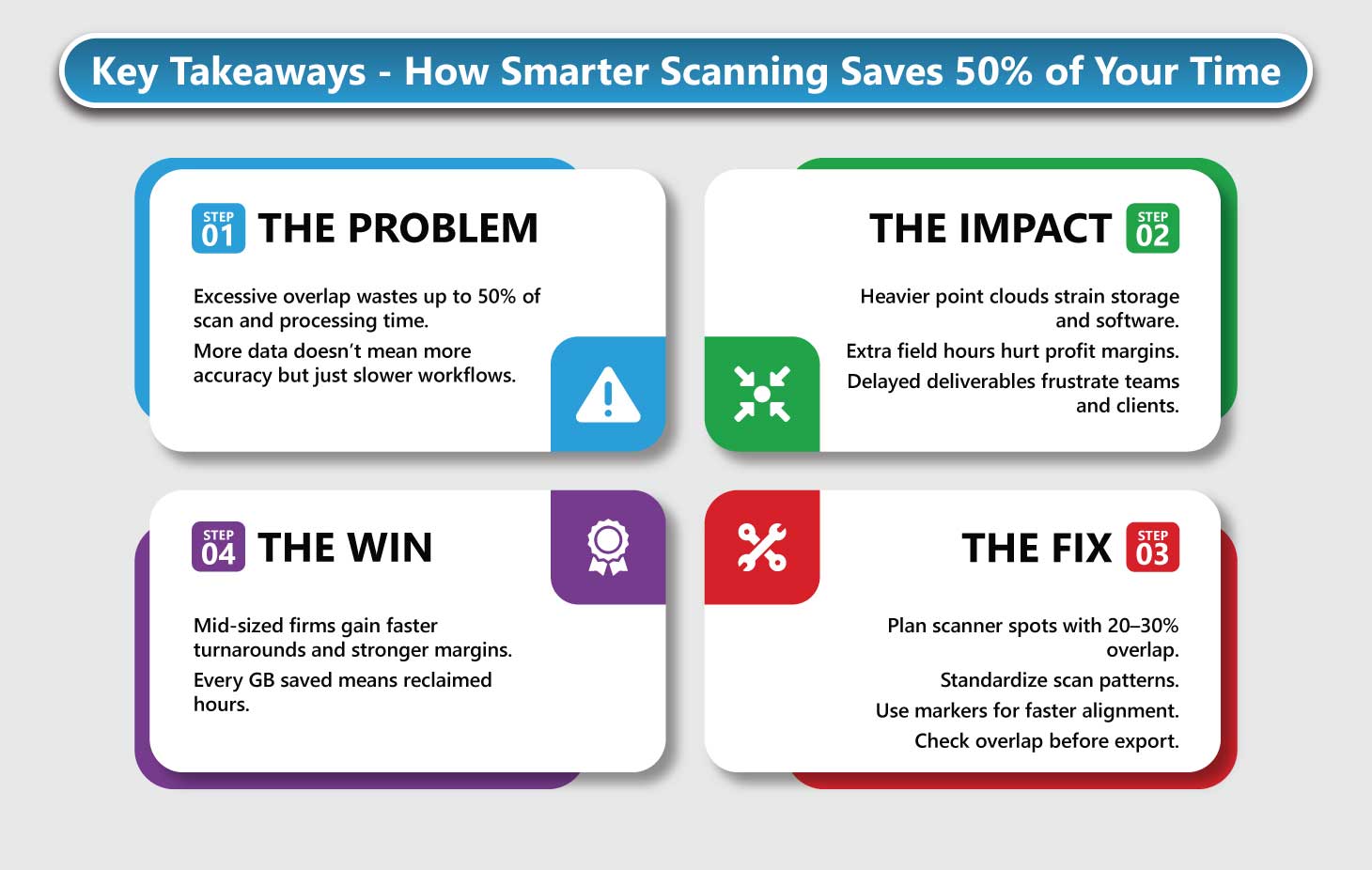

Introduction: When “Just to Be Safe” Slows Everything Down

Let's assume your team is on-site, laser scanner humming, capturing every inch of a corridor. Just for safety, they scan the same area again from a little different angle. And then again. It feels like a careful move, ensuring full coverage, no blind spots, no missing geometry. But by the time the data hits your desktop, the real problem shows up.

That “extra safety” has turned into extra work:

- Duplicate scans that add no measurable accuracy

- Massive point clouds that strain software and storage

- Longer registration time before anyone can even start modeling

Many architecture firms lose up to half of their scan and processing time this way, not because of poor technology, but because of avoidable overlap errors. The fix lies not in new tools, but in better planning and smarter scanning habits.

Why Overlap Data Matters and When It Becomes a Problem in 3D Laser Scanning

In 3-dimensional laser scanning, the overlapping simply means two or more scans share the same space. Some overlap is critical, most probably around 20–30%, to help registration software find common points and stitch scans together accurately. Without the process, you may risk gaps or misaligned geometry.

But here’s where good intentions backfire. Go beyond that range, and every extra pass starts working against you. The scanner collects the same walls, ceilings, and floors, again and again, which does not improve accuracy, just adds digital weight.

What happens next:

- Registration slows down because the software has to process unnecessary data.

- Files become overstuffed, eating up storage and computing power.

- On-site time stretches, even though nothing new is being captured.

For architecture firms running lean teams, this subtle overlap mistake can quietly double scanning time and delay every project downstream.

Why the Overlap Data Mistake Happens in Scan to BIM Process

If controlling overlap is that simple, why do we keep allowing it to happen? The answer lies in a combination of misunderstandings regarding accuracy, bad habits, and lack of coordination that even experienced teams fall into.

Here’s the source of the problem:

- Misunderstanding about accuracy: Many field technicians believe that overlap equals more data, and therefore more accuracy. What may be surprising is that, beyond 30%, the additional coverage provides no measurable difference in precision, only increasing the processing time.

- No established scanning protocol: If there are no established guidelines around what overlap is reasonable, scanner position and overlap for any project is driven by the technician, the project and, in some cases, the technician’s mood. All of which makes scheduling unpredictable.

- Disconnect from field to office: The scanning team is largely working independently of the field to office feedback loop of the registering and modeling processes. Thus field effort is managing all the post-processing work unnecessarily.

- Human bias and habit: Technicians are prone to over-scan “just to be safe” under tight deadlines or a scope of work that is unclear.

For the growing architecture firm and company, these small habits slowly deteriorate productivity — project after project.

The Hidden Cost of Excessive Data Overlap in Scan to BIM Projects

Excessive overlap may seem harmless initially; after all, it feels like being thorough. But the truth is, it quietly wastes time and energy across every stage of a building construction project.

- Field time wasted: More scan positions mean longer site visits. A task that should be completed in just four hours easily stretches to six, not because the site is critical, but because the same walls and corners are being scanned from various angles.

- Data overload: Useless scans create massive point clouds that can slow down even the fastest software and utilize storage. Managing all this extra data can also increase project costs and complexity.

- Registration drag: More overlap means software has to reconcile the same geometry again and again. Alignment, verification, and the QA process all take more time, delaying the next steps.

- Downstream delays: Modeling teams receive enormous datasets, slowing the production of ready to use BIM models or construction drawings.

For many mid-sized firms, a single day of scanning can hide up to 3 hours of unnecessary duplication. It’s not just wasted time, it’s a silent drain on both productivity and profits. Here, the better fix is enhanced coordination on-site and a simple, consistent scanning standard that keeps every scan useful.

Common Scanning Mistakes That Waste Time

| Common Mistake | Description | Estimated Time Wasted |

|---|---|---|

| Setting overlap too high | Using 80%+ overlap when not required | 30–40% |

| Flying too slowly | Maintaining overly conservative drone speed | 20–25% |

| Not optimizing flight path | Inefficient or non-systematic flight patterns | 15–20% |

| Excessive buffering | Scanning 20m+ beyond project boundaries | 10–15% |

| Re-scanning unnecessarily | Failing to verify coverage before repeating flights | Up to 100% |

Why Mid-Sized Architecture Firms Feel the Data Overlap Pain the Most

For many mid-sized architecture firms, scanning is less of just a task, and more of managing a number of deadlines, a budget, and limited team resources. For these reasons, the impact of overlap data error in a laser scanning project is keenly felt by small and mid-sized architecture firms.

- Lean teams, high expectations: These firms must manage complex projects without a dedicated scanning operator or specialist. Hours spent in the field are important.

- Relying on generalist staff: Scanning is frequently executed by in-house architects or contractors who do not follow the identical and specific overlap guideline. This leads to inconsistency and duplicate data.

- Effect on margins: Every additional hour spent capturing duplicates or redundant scans has a direct impact on profit margin and the project delivery schedule.

- Perception versus reality: The over-scan approach feels "safer." However, this invisible productivity leak is time, energy, and resources lost across project work.

For the decision maker to understand this hidden inefficiency is important. Addressing this inefficiency can help mid-sized firms gain back field time, eliminate reduction in processing redundancy, and improve overall project efficiency, therefore maximizing office operations without adding staff.

Resolving the Overlap Problem: Intelligent Planning, Quicker Outcomes

Overlap issues are not a hardware issue; they are a workflow issue. By making some intelligent adjustments, mid-sized architecture firms can save hours in fieldwork and processing time, with no loss of accuracy.

Here’s a method for increasing your control of the scanning process.

- Pre-scan preparation: Begin with your floor plan. Determine where the scanners will be located and the zones of overlap (20–30%). Your placement of the scanners can limit blind spots without generating a significant amount of excess data.

- Scanning patterns: Develop patterns and sequences, for example, taking a zig-zag approach down a corridor, or a grid layout in open spaces, so all technicians scanning are doing it in the same way.

- Visual markers or targets: Simple markers allow software to align scans much quicker and with better accuracy and allow you to reduce the overlap process.

- Optimize in registration: Many registration tools, such as Leica Cyclone, Autodesk Recap, or FARO Scene will give you overlap detection options prior to exporting data, great for avoiding massive datasets.

- Training & checklists: A brief 10-minute overlap check prior to scanning could save you hours later in the registration process.

Tip: You do not have to scan the same wall three times, provided everyone on the team scans it at the same confidence level.

For growing companies, consistency is essential to speed, accuracy, and trust - within the team, and also with clients who are expecting fast and reliable results.

How Leading Firms Turn Data Overlap Control into a Competitive Edge

Top architecture firms do not see scanning as a guess anymore; they now see it as a repeatable and data-driven process. By creating standardized scanning workflows and defining the ratios of overlap, they are able to take something potentially time-draining and repetitive and create faster and more consistent scanning procedures.

Here's what they are realizing:

- Faster turnaround of their projects: Less redundant data has scans registering in hours, not days.

- Easier modeling workflows: Cleaner point clouds allow for more seamless BIM and as-built production.

- Predictable outcomes: Reduced surprises, revisions, and delays due to consistent overlap control.

The data discipline is what separates the best firms. They do not just scan; they are creating a system for efficiency, reliability, and better collaboration on each renovation or scan to BIM project.

Closing Thought: Smarter Scans, Stronger Projects

Ultimately, a more efficient scan means not having the latest technology; it means knowing how to best utilize it. A 3D laser scanning can only be as efficient as the overlap strategy you develop. Eliminate redundancy but not quality, and you will reduce your timeframe.

For mid-sized architecture firms, even minor procedural changes can yield savings, both time and cost. Start by reviewing a project over the past week. How much of that point cloud was actually needed? The results will surprise you.

A little more thoughtful planning today requires smarter, faster, better data, and you can have a better competitive edge.

The Next Step: Allow our Scan to BIM specialists to take your point clouds and transform them into clean, precise, ready-to-use models, saving you time, eliminating redundancy, and allowing you and your team to spend time on the real work, designing and delivering great projects.